Application of logistic simulation on an assembly line

Demand:

- Comparison of different robot lane layouts

- Determination of the optimum number of transport robots

- Determination of the maximum load time demands

- Improof of the planning reliability

Service:

- Modeling of two different plant concepts in Taylor II

- Programming of an order generation with adjustable statistic distribution

- Two-parameter field optimization(#transport robots, load time) in a sequence of simulations

- Proof on robustness of the plant concept against uneven distribution of the main assembly line orders

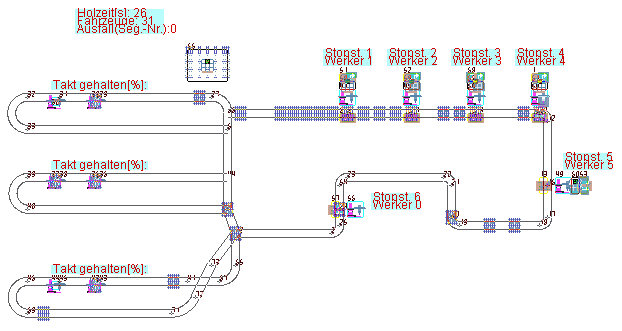

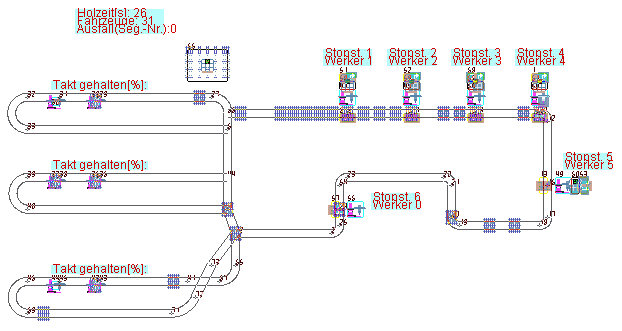

The picture shows the simulation model with a robot lane layout with the load terminals. The different cages

symbolize loaded and empty transport robots. (Taylor II Animation view)